A web journal about craft methods of distillation

Editors: Will Hodges & Ansley Coale

Individual Product: Germain-Robin Single Barrel V320 Riesling

Individual Product: Germain-Robin Single Barrel V320 Riesling

Distillery Post: 2nd half of the Distillation Season

Distillery Post: 2nd half of the Distillation Season

–

We have begun to distill Pinot Noir and other red varietals at the distillery this week. Pinot Noir is our favorite grape to distill and makes up a large portion of the Select Barrel XO.

Final distillation of Pinot Noir from Roederer Estate of Anderson Valley. They used a particular yeast strain called Melody in this batch of wine to give it a more robust and complex profile.

The copper bucket below is set up for catching any distillate in transitioning between cuts as we transfer the condenser’s output from one holding tank to another. At the distillery these tanks are affectionately known as the “hotdog” and “coffin”. Above, samples directly off the still await. Joe will determine when to make the cuts on sense of smell.

The beginning of 2015 distillate “Blend B” that we offer for sale to wineries for their ports. This one is Dolcetto from John Mattern’s Split Rock Ranch in Talmage near the City of Ten Thousand Buddahs and Viognier from Rivino between Ukiah and Hopland along the Russian River.

Individual Product: Low Gap 4yr Wheat Whiskey

Individual Product: Low Gap 4yr Wheat Whiskey

Individual Product: Low Gap Straight Bourbon

Individual Product: Low Gap Straight Bourbon

Individual Product: Mezcalero 14

Individual Product: Mezcalero 14

Notes from Ansley: Early Germain-Robin Part 3 Installing the Still

Notes from Ansley: Early Germain-Robin Part 3 Installing the Still

*

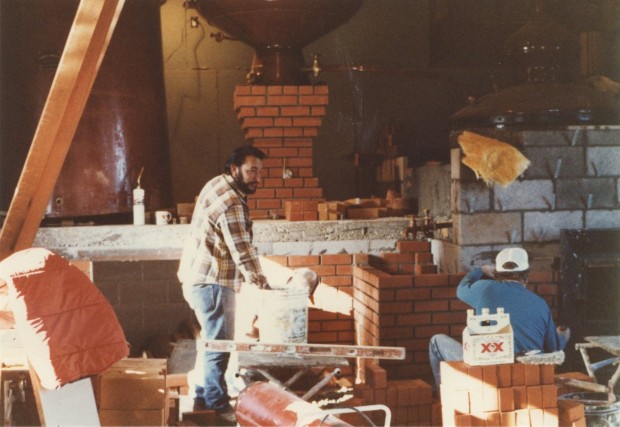

We worked with local masons Fred Rouse and Dave Butler. They didn’t believe us when we told them that this was the only such still in the USA.

We had a scale drawing made by Prulho, in centimeters. There was a lot of jawboning.

Here it is in place before they put the bricks around the pot. We insulated the pot with earth, sand, and diatomaceous earth, the way they used to. This means there is retained heat, which is beneficial around the pot. The same heat dissipates with modern cognac-still insulation.

Dave and Fred laying the brick facing. Behind Dave is the brick pillar they built to hold the preheater. Elegant work.

Fred Rouse’s crew. They enjoyed the job.

Turkish workman Ansley checking it out. Note the rebar for finishing the chimney behind the pot and the leftover firebrick under the condenser platform.

Our lovely old, antique still. It makes very good brandy. We moved the operation in 1998, but we still use it once in a while.

Distillery Posts: Preparing Pear Maceration for the Pear de Pear Liqueur

Distillery Posts: Preparing Pear Maceration for the Pear de Pear Liqueur

*

Today we prepared some beautiful Bosc pears for maceration in pear distillate. The infusion will be added to pear brandy distilled from Bartletts to make our Pear de Pear liqueur.

The pears come from the Filigreen orchard in Anderson Valley, where we also source some heirloom apples. They are small, thus intensely flavored, and will improve our pear brandy with “clean and yummy” (Joe Corley) flavors and aromatics. These Boscs are ripe and very sweet therefore it’s great to be able to add an appealing fruity sweetness to the brandy without resorting to sugar.

Bosc Pears

Milling the pears Jeff Desjardins

Jeff Desjardins

Greg Peacock

Crispin Cain’s of Tamar Distillery’s New Release: Straight Bourbon

Crispin Cain’s of Tamar Distillery’s New Release: Straight Bourbon

*

From Crispin Cain of Low Gap Whiskey:

Low Gap Bourbon, released today, is the pinnacle of our whiskey production. I am pleased with my bourbon’s first showing. The Bourbon was inspired by my maternal Grandfather, Ted Ultsch, a devout bourbon man. I brought him a bottle of Germain-Robin in 1991 and he sent it back to me unopened, saying he drinks ONLY bourbon! He lived to be 94, passing away peacefully while napping right after winning $500 playing craps in Reno.

I made my first whiskey at home in 1992 when I got ahold of a 5-gallon bucket of the same barley malt used to make Red Tail Ale.

When I made the prototype of the Malted Wheat Whiskey in 2008 at Greenway Distillers, I knew then the possibilities for making the best whiskey ever. In 2010, we started making whiskey in earnest, but I waited to make bourbon until I was fully confident about the whole production process.

The nose is full, with butter, vanilla, sweet corn, and oak. At 43.2% ABV the bourbon is approachable and smooth. Extremely likeable and friendly, this whiskey is both something to keep and something to share.

The bourbon’s mash bill includes 65% corn, 20% malted barley, and 15% malted rye. Complete fermentation to dryness, and double distillation in an old Cognac still, lend this whiskey its best qualities. A straight bourbon, it has been aged for two years in new bourbon barrels.

Notes from Ansley: Early Germain-Robin Part 2

Notes from Ansley: Early Germain-Robin Part 2

The Still Arrives

Hubert found a beautiful still, wood-fired when assembled in the 1930s, in an abandoned distillery near Cognac. He had it refitted at Prulho, who added two coils to the condenser and shipped it to California.

I had a 16-foot flat bed truck. We figured we could put the container on it, and drove it to the Port of Oakland. WRONG. When the crane tried to load it, it almost blew the tires. The importer took the container to his warehouse and put the crates on this flatbed. Here I am on the way out of Oakland.

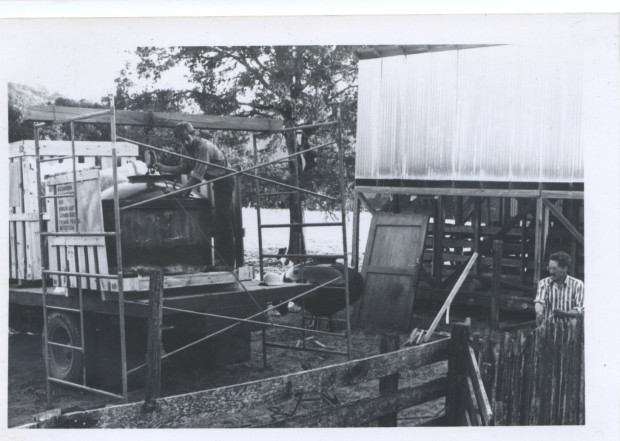

When we got to the ranch, we didn’t want to rent a forklift to unload it.

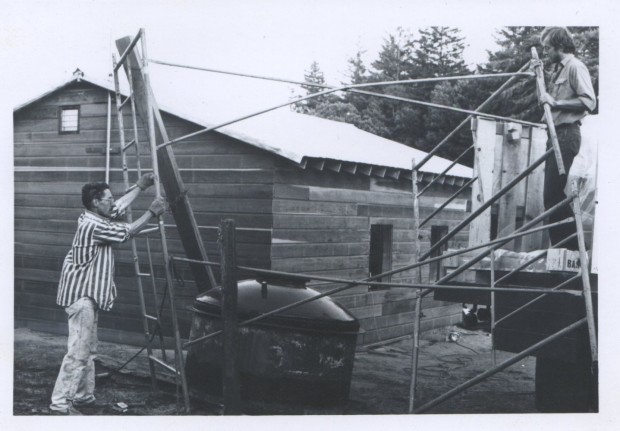

So we took the braces off one side of the scaffold, put a beam at the top, attached a block & tackle, backed the truck underneath the beam, and hooked it to the still’s main pot. You can see the preheater on the ground behind the scaffold. Then we drove out from underneath it.

The scaffold slowly and gracefully warped, depositing the pot on the ground like a baby’s kiss. It was a magic moment.

Here’s the pot on the ground. You can see where the scaffold frame bent.

Notes from Ansley: Early Germain-Robin Part 1

Notes from Ansley: Early Germain-Robin Part 1

The Beginning

In the summer of 1981, I picked up a hitchhiking Hubert Germain-Robin, whose family had produced cognac since 1781. He told a sad tale of industrialized production, and wanted to return to ancestral methods. He went back to Cognac to look for an old hand-operated still. In June, 1982, I dug the foundation for a small distilling shed up on my ranch. We had zero money: I dug the footings and leveled the site with a mattock and shovel, and poured a slab.

In August, Hubert arrived and helped me put up the shed.

This is me cutting into a stud for a diagonal brace. I found that old metal-cased Craftsman skillsaw in the ranch shop in 1973. I used it for 20 years.

Hubert is holding a center rafter (notice the notch) while I get some nails.

Nailing the rafter.

We used old-fashioned, channel siding and a metal roof, and found old sliding barn doors at a junk-yard.

Here’s how it looked in November, 1982.

Notes from Ansley: Sauvignon Blanc

Notes from Ansley: Sauvignon Blanc

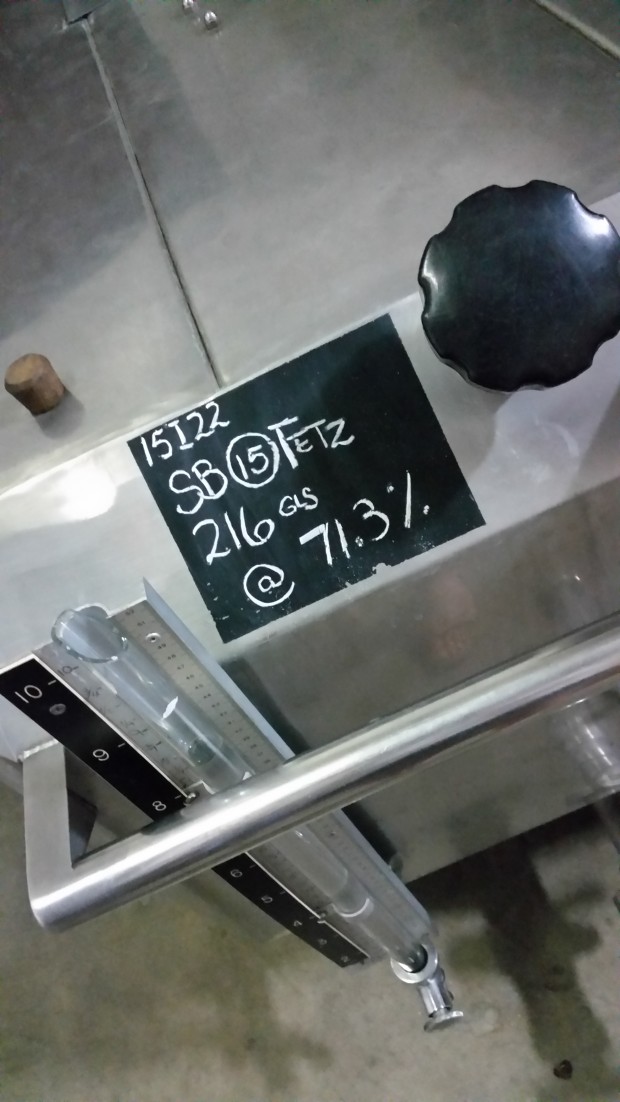

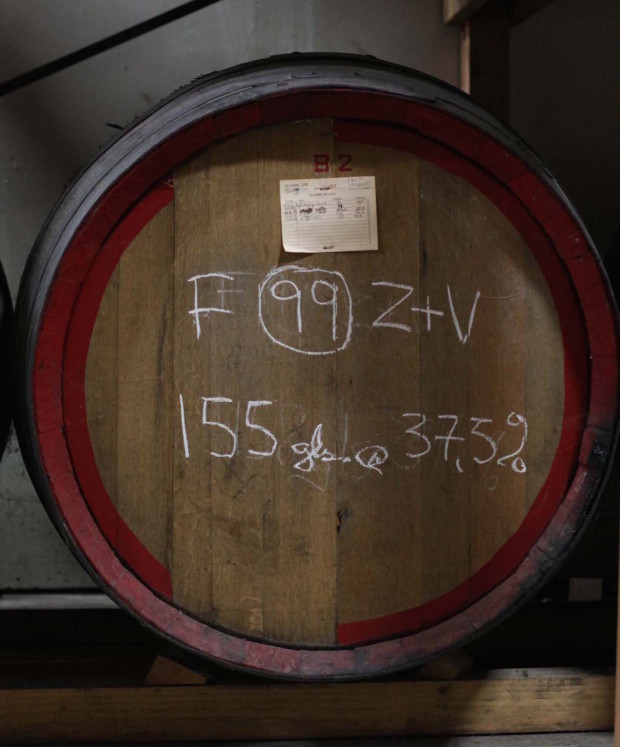

We’re close to an end of the second distillation of a batch of heavy-solids wine we bought from Fetzer. Sauvignon Blanc (a rarely-used but legal grape in Cognac) has an unusual “savage” (I say “feral”) overtone, especially on the palate. “Untamed” is another word. I was once shown an aged cognac from Sauvignon Blanc which had the same ferality. The photos show Joseph Corley checking to see how close we are to the end of the “seconds”, the chalk label on the tank that we make the fresh brandy into (later moved to barrels), and me smelling one of the best Sauvignon Blancs we’ve made: very clean, very aromatic, and pretty soft for fresh distillate at 71%. We like working with these grapes that are rarely or ever distilled: Chenin Blanc, Riesling, Semillon, Muscat. They lend unusual complexity to our blends. Some of today’s brandy will end up in the Old Havana.

Notes from Ansley: Giving Birth to Russell Henry

Notes from Ansley: Giving Birth to Russell Henry

One of the first bottles of Russell Henry London Dry just before getting its label. It got there from countless hours of creative work: adjusting a unique mix of botanicals, finding the right GNS, making the right cuts on the small cognac still, choosing the bottle/cork/foil, designing and printing the label: the cumulative input of 10 human beings, plus the crew that is running the bottling line. In a way it’s like a birth, all that effort focused into this one glass full of a unique distilled spirit. Here’s footage of the bottling day.

Here is footage of the bottling line in motion

Notes from Ansley: Straight Talk about Johnnie Walker Blue

Notes from Ansley: Straight Talk about Johnnie Walker Blue

Don Sutcliffe of The Exceptional sent me this. As he says, brilliant. This brand and others like them are what keep distributors running: without them, no trucks, no salespersons, no warehouses, no way of reaching more than a handful of consumers. On the other hand, such brands are like a pervasive dense fog between the consumer and genuinely great craft spirits. What Ralfy says about brands seems obvious but it’s not widely understood.

Tech Note: Interview with Karina Abad on Organizing Production

Tech Note: Interview with Karina Abad on Organizing Production

Tech Note: Three Stills at Los Danzantes

Tech Note: Three Stills at Los Danzantes

Tech Note: How Los Danzantes Does Their Work

Tech Note: How Los Danzantes Does Their Work

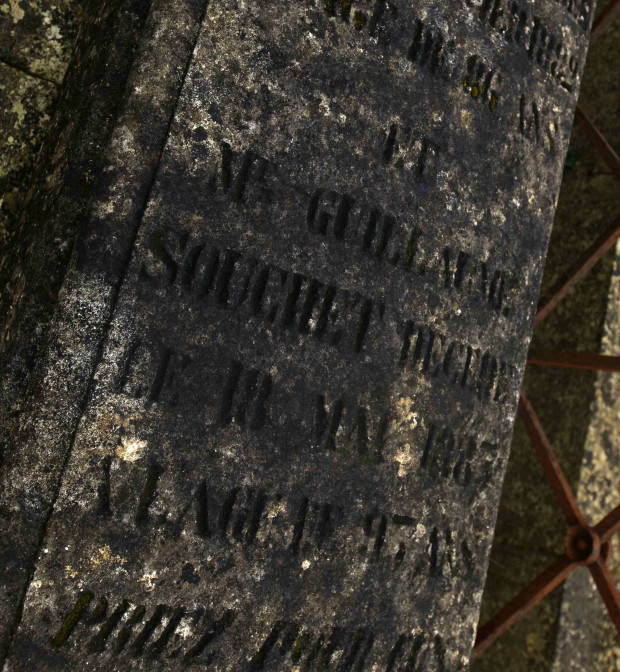

Distillery Notes: Jarnac, France. The Location of Maison Surrenne

Distillery Notes: Jarnac, France. The Location of Maison Surrenne

Tech Note: Using a Hoga Potstill for Mezcal from Tobalá Agave

Tech Note: Using a Hoga Potstill for Mezcal from Tobalá Agave

Tech Note: Distilling Mezcal from Wild Tobalá

Tech Note: Distilling Mezcal from Wild Tobalá

Distillery Posts: Adjusting to Proof with Old, Understrength Brandy

Distillery Posts: Adjusting to Proof with Old, Understrength Brandy

Just before bottling, we often have to slightly dilute a brandy so it’s at the same proof as we say on the label, which has already been printed. So we create and use aged faibles, slightly understrength brandies, of various ages (one is almost 30 years old) so the dilution is with something congruent, in fact adds a tiny complexity.